What's really in supermarket poultry: Chemical sludge. 'Meat glue'. Pig skin. If only water was ALL they pumped into your chicken

Joanna Blythman

- Investigation revealed some chicken breasts on sale are 20 per cent water

- Sold in the aisles of major retailers such as Aldi, Asda and Iceland

- It is not illegal to add water and additives to chicken

After the horsemeat scandal of earlier this year, we now have the chicken fiasco, where major chains have been exposed for selling frozen chicken with shockingly high levels of added water.

An investigation this week revealed that some chicken breasts on sale in the UK are made up of no less than 20 per cent water.

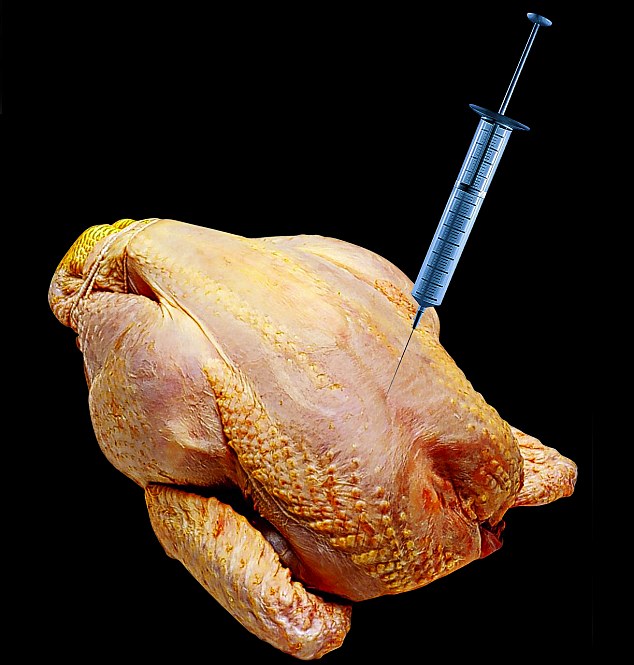

What you think is a juicy chicken breast may in fact have been pumped full of water, either mechanically injected or through an industrial process known as tumbling — and what is worse, chemical additives are also added during the procedure.

Additives: What you think is a juicy chicken breast may in fact have been pumped full of water, either mechanically injected or through an industrial process known as tumbling

The study highlighted one case of raw, frozen chicken breasts imported from Brazil into Britain and then sold in our supermarkets.

While still in Brazil, salt and corn oil were added to the chicken breasts. Once in Britain, the breasts were thawed out and put through the vacuum-tumbling process.

This saw water and chemical additives absorbed into the meat, increasing its weight and giving it a juicier, but wholly unnatural, texture.

The breasts were then re-frozen and sold in the aisles of major retailers such as Aldi, Asda and Iceland.

A curious double standard seems to be in operation here: home cooks are sternly warned never to re-freeze previously frozen meat, unless they have cooked it thoroughly.

But behind the scenes of food manufacturing, frozen meat is being defrosted, pumped up with water and additives, then re-frozen all over again, and consumers are none the wiser.

It is not illegal to add water and additives to chicken, as long as the additions are clearly displayed on the label. But the technical legalities are not the only issue here.

There is also the unfairness of asking the public to pay more for a product than is justified.

Many of us will feel cheated at the thought of having to pay for the added water, which works out at up to £1.54 a kilo.

What’s more, these tumbled chicken breasts are a symbol of how heavily-industrialised, intensive production now dominates the food chain, robbing the public of the natural flavours and wholesome goodness that we ought to expect from a succulent chicken breast.

What is particularly worrying is that we do not yet know the implications for our health, since there has been no in-depth analysis of the consequences of eating these adulterated meats.

But it is hardly likely that eating chicken filled with water, salts, oil and additives will prove beneficial.

As the GM controversy continues to demonstrate, working against nature is rarely a good idea. And that is precisely what is being done here.

Normally, when meat is cooked, it loses liquid, but the meat processors are doing precisely the opposite, by actually pumping in fluids containing a cocktail of chemicals.

"Their art consists of taking a pig’s ear — sometimes literally — and turning it into a profitable silk purse."

- Joanna Blythman

Though this week’s news has focused on chicken, the technique of adding water and additives is applied to a vast range of produce, including ham, bacon, frankfurters, sausages, turkey rolls, luncheon meat, sandwich fillers and ready meals.

Indeed, almost any low-grade, mass-produced, frozen or processed meat will have been treated this way.

And it goes beyond meat. Even seafoods such as scallops are regularly soaked in water with phosphates to increase their size — though inevitably much of the taste is lost.

The sheer number of foods that are adulterated in this way attests to the boundless creativity, advanced technology and cost-cutting zeal of the food processors.

Their art consists of taking a pig’s ear — sometimes literally — and turning it into a profitable silk purse.

Their central objective is to make the meat or seafood absorb a significant quantity of water.

The rationale is simple. Water is cheap and easy to source. Meat is much more expensive.

The result of this process is inevitably that the customer ends up paying way over the odds for the water. The controversial process usually begins when the manufacturer acquires his supply of what is called ‘trim’, usually pieces of boned, frozen meat.

His next task is to bulk out the trim by getting it to absorb water and additives. For this to happen, the manufacturer has to create a ‘brine’, a chemical solution that will encourage the meat to retain liquid using binding agents.

These binding agents are usually from five main sources, which can be used separately or mixed together.

The first is transglutaminase, an enzyme that is essentially a natural glue. Indeed, it is sometimes called ‘meat glue’. The second is from a group collectively known as hydrocolloids, substances that form a gel on contact with water.

These hydrocolloids include carrageenan, which is derived from seaweed, as well as the exotically named locust bean gum — extracted from the seeds of the carob tree — and guar gum, which derives from ground guar beans.

The third widely-used agent, especially in seafood, is phosphate, which is taken from phosphoric acid and is valued for its ability to make oil adhere to water.

The fourth is fibre, made from a source such as wheat, citrus or cellulose.

And the fifth is protein powder, which is made by extracting collagen from pigs’ skins.

Protein powder comes in several different forms, such as pork pellets and broth powders — made from dehydrated, skimmed chicken stock. There is also a soya protein that tends to be made from genetically modified crops.

Once you know this, none of our mass-produced foodstuffs sound remotely appetising.

But it gets worse, for the next task is to get the brine into the meat. This can be done in two ways.

The first is through vacuum- tumbling, the method that has been in the news this week.

The most common approach when it comes to vacuum-tumbling is for the meat to be placed with the brine in a machine that looks like a concrete mixer. The meat is then agitated as the mixer spins, the continual turning accelerating the absorption.

The second method is the injection of the brine straight into the structure of the meat through a series of needles attached to an instrument that looks rather like a steel brush.

One company has boasted that, through the injection method, 100 kilos of meat can be easily bulked up to a weight of 165 kilos with the addition of brine.

It is no wonder that the manufacturers have so eagerly embraced all this tumbling and injecting.

An internal brochure for the industry captures this enthusiasm, explaining that the process ‘transforms worthless cuts of meat with low value into standardised portions with a high added value’.

In promoting this approach, the industry uses overblown language that extols the improvements brought about by the process.

So processed meats are ‘easier to slice’ and feel ‘succulent but firm’. Each mouthful is ‘slightly resistant but juicy’.

Other products are praised for their ‘cohesiveness’, as if that were a quality that the public actually look for in a piece of meat.

‘Mmmm, I really like this chicken breast, it’s so cohesive,’ they imagine us saying as we tuck into our dinner. That just shows how far the manufacturers have departed from reality.

But it is all a huge con. Whatever language the manufacturers use, the public are getting neither value nor taste. This is not the way meat should be eaten.

The ham we find in our petrol station sandwiches has the consistency of a limp handshake and all the flavour of an old tyre precisely because it has been through such a destructively intensive process, pumped up with water and held together by chemical gel.

Those who suffer the most are those who eat in fast food restaurants and big institutions such as schools, hospitals and the British Army, where the needs of mass catering and limited budgets leave the managers vulnerable to the bulk merchants.

Yet our reliance on ‘restructured’ and ‘reformed’ meats and chemical ‘emulsions’ is a false economy.

This is not real, natural meat, but an industrialised meat-like substance.

Eating cheap meat like this is a mug’s game — we may think we are getting a bargain, but we are paying through the nose for water and chemicals that can’t positively do us any good.